传输范围:0.17~5.5μm;折射率:No 1.75449 Ne 1.74663(1.06μm);反射损耗:14% at 1.06μm;吸收系数:0.3×10 -3 cm -1 at 2.4μm ;规格(D×L):18.0×4.0mm;方向:Random;应用范围:IR抛光

✱因产品升级或技术原因,产品配图可能有出入,具体请咨询客服!

| 货号 : A80161443 | |

| 库存 : 请咨询客服 | |

| 货期 : 请咨询客服 | |

| 点右侧在线咨询 | |

蓝宝石Al2O3 因其极度的韧性和强度可以很好的应用为UV,VIS和NIR光谱波段的光学窗片材料。

蓝宝石具有多种生长方式。 Verneuil和Czochralski方法通常用于标准级蓝宝石材料。 更高质量的蓝宝石,应用于电子基板的由Kyropulos生长制造,这可以得到非常高的纯度,具有优良的紫外透射特性。 在IR中的使用范围被限制在约5μm,并且在任何光学级别中遇到很少的困难。 它在紫外线范围内,必须注意观察,因为从140nm到240nm的透射对杂质和间隙空位非常敏感。大片蓝宝石可以通过色带生长制成。 蓝宝石具有轻微的双折射性,通常的IR窗口通常以随机的方式从晶体切割,也有对于双折射的特定应用,选择取向。 通常这是光轴与表面平面成90度,称为“零度”材料。 合成光学蓝宝石没有着色。

*请注意,所有制造商似乎对热膨胀的实际数字不统一!

技术参数:

传输范围: | 0.17~5.5μm |

折射率: | No 1.75449; Ne 1.74663(1.06μm)(1) |

反射损耗: | 14% at 1.06μm |

吸收系数: | 0.3×10 -3 cm -1 at 2.4μm (2) |

吸收峰: | 13.5μm |

dn / dT: | 13.4×10 -6(0.546μm)(3) |

dn /dμ= 0: | 1.5μm |

密度: | 3.97g/cm3 |

熔点: | 2040℃ |

热导率: | 27.21W m-1K-1 at 300K |

热膨胀: | 5.6(para)& 5.0(perp)×10-6 / K * |

硬度: | Knoop 2000 with 2000g indenter |

比热容量: | 763JKg-1K-1(293K)(4) |

介电常数: | 11.5(para)9.4(perp)at 1MHz |

杨氏模量(E): | 335GPa |

剪切模量(G): | 148.1GPa |

体积模量(K): | 240GPa |

弹性系数: | C11 = 496 C12 = 164 C13 = 115 C33 = 498 C44 = 148 |

表观弹性极限: | 300 MPa(45,000 psi) |

泊松比: | 0.25 |

溶解度: | 98×10-6g / 100g water |

分子量: | 101.96 |

类/结构:(hex),R3c | Trigonal(hex),R3c |

光谱透射曲线:

折射率:(No = Ordinary Ray Ne = Extraordinary Ray)

um | No | Ne | um | No | Ne | um | No | Ne |

0.193 | 1.9288 | 1.9174 | 0.213 | 1.8890 | 1.8784 | 0.222 | 1.8754 | 1.8650 |

0.226 | 1.8702 | 1.8599 | 0.244 | 1.8506 | 1.8407 | 0.248 | 1.8470 | 1.8372 |

0.257 | 1.8393 | 1.8297 | 0.266 | 1.8330 | 1.8236 | 0.280 | 1.8244 | 1.8151 |

0.308 | 1.8110 | 1.8020 | 0.325 | 1.8047 | 1.7958 | 0.337 | 1.8001 | 1.7921 |

0.351 | 1.7969 | 1.7882 | 0.355 | 1.7960 | 1.7883 | 0.442 | 1.7804 | 1.7721 |

0.458 | 1.7784 | 1.7702 | 0.488 | 1.7753 | 1.7671 | 0.515 | 1.7730 | 1.7649 |

0.532 | 1.7717 | 1.7636 | 0.590 | 1.7680 | 1.7600 | 0.633 | 1.7659 | 1.7579 |

0.670 | 1.7643 | 1.7563 | 0.694 | 1.7634 | 1.7554 | 0.755 | 1.7614 | 1.7535 |

0.780 | 1.7607 | 1.7527 | 0.800 | 1.7601 | 1.7522 | 0.820 | 1.7596 | 1.7517 |

0.980 | 1.7561 | 1.7482 | 1.064 | 1.7545 | 1.7466 | 1.320 | 1.7501 | 1.7423 |

1.550 | 1.7462 | 1.7384 | 2.010 | 1.7375 | 1.7297 | 2.249 | 1.7323 | 1.7243 |

2.703 | 1.719 | 1.711 | 2.941 | 1.712 | 1.711 | 3.333 | 1.701 | 1.693 |

3.704 | 1.687 | 1.679 | 4.000 | 1.674 | 1.666 | 4.348 | 1.658 | 1.65 |

4.762 | 1.636 | 1.628 | 5.000 | 1.623 | 1.615 | 5.263 | 1.607 | 1.599 |

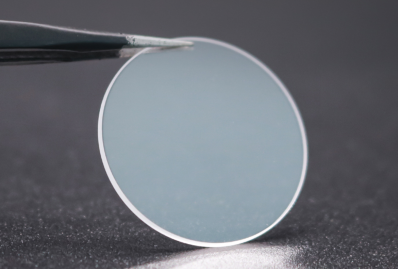

蓝宝石(Al2O3)圆形窗片:

订购信息:

订购型号 | 规格(D×L) | 方向 | 应用范围 |

SAPP10-2 | 10.0×2.0mm | Random | IR |

SAPP12-1 | 12.0×1.0mm | Random | IR |

SAPP12-2 | 12.0×2.0mm | Random | IR |

SAPP12-4 | 12.0×4.0mm | Random | IR |

SAPP15-2 | 15.0×2.0mm | Random | IR |

SAPP18-4 | 18.0×4.0mm | Random | IR |

SAPP20-2 | 20.0×2.0mm | Random | IR |

SAPP25-0.5 | 25.0×0.5mm | Random | IR |

SAPP25-1 | 25.0×1.0mm | Random | IR |

SAPP25-2 | 25.0×2.0mm | Random | IR |

SAPP25.4-1 | 25.4×1.0mm | Random | IR |

SAPP26-1 | 26.0×1.0mm | Random | IR |

SAPP35-2 | 35.0×2.0mm | Random | IR |

关于晶体切割:

Sapphire is slightly birefringent and so for critical optical or mechanical applications, the windows should be specified as 'zero degree', or 'c-cut', meaning that the optical axis of the material should be perpendicular to the plane of the window. If unspecified, the component will be of 'random' cut, but its worth noting that this is nearly always 60° to the optic axis as this is the 'softest' direction for the saw. Note that all sapphire is always single crystal, sub-grains are always avoided in the cut.

C-plane (0,0,0,1) = Z-cut

A-plane (1,1,-2,0) = Y-cut

M-Plane (1,0,-1,0) = X-cut R-Plane (1,0,-1,0)

Manufacturers seem unable to agree on the thermal expansion coefficient of sapphire, figures from 5.6 to 8.4 x 10-6 K are given. While there may be some variation due to the method of growth, and certainly due to the axis of cut, this variation is inexplicable.

| 名称 | 型号货号 | 描述 | 参数 | 价格 |

|---|